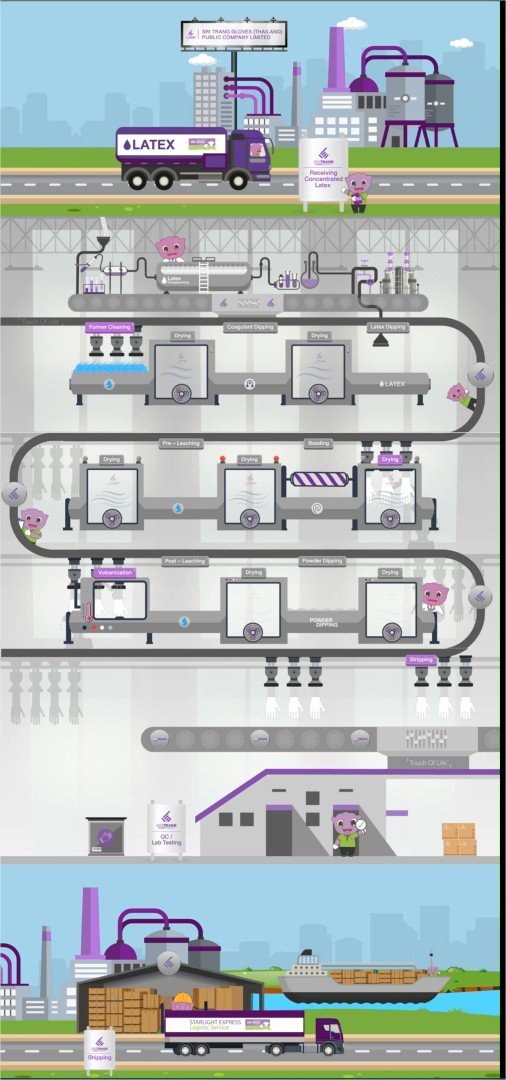

How STGT gloves are made

We operate production lines in 3 gloves factory locations producing more than 49.5 Billion pieces of disposable rubber gloves per year.

Selecting the concentrated latex and Nitrile butadiene rubber

At STGT our expertise are fuse with both Natural rubber and Nitrile rubber. We focus on every detail of raw material from Ammonia, Protein content in natural latex, coagulum and many other contents.

After Natural latex and Nitrile sourcing, other ingredients are add in to form the right formula for each type of gloves. We see our expertise as the rubber chef who create the recipe for .

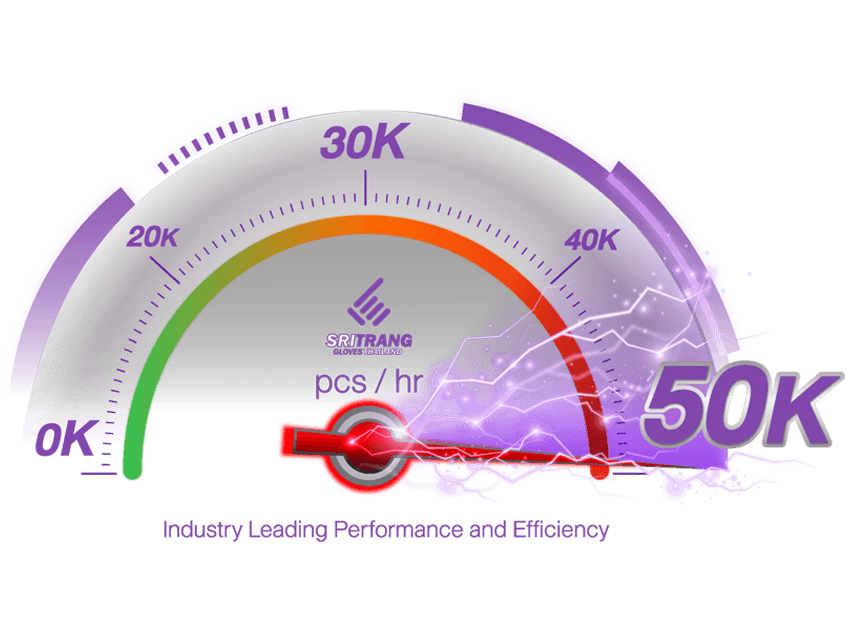

Incredible Performance

The engineering team at STGT designed and developed one of the fastest production machines in the world! The industry leading machine is able to reach record outputs of more than 50,000 pieces of high quality medical gloves per hour. The engineering team at STGT has more than 30 years of experiences in medical glove production, which helped STGT realize one of the most powerful medical glove production machines. Apart from performance, STGT machines utilize our state of art waste management system combined with Biomass energy to remain environmentally friendly. This continues to solidify STGT as a truly glove maker.

Extremely Resilience

Our versatile production lines were designed with performance and flexibility in mind. We build machines that are extremely resilient, and they can readily switch between Latex and Nitrile glove manufacturing. Additionally, the product lines are able to produce different specifications in order to meet the demands of a rapidly changing and growing global market.

Highly Tunable

STGT glove production machines are built for the future with highly tunable technology. We can endlessly upgrade each part of our production line to maximize performance and efficiency. Because of these unique characteristics, STGT is able to continuously improve our products with minor fine-tuning to existing equipment. This ensures a steady supply of product, as production lines do not need to shut down for extended periods or prolonged upgrade projects. STGT is built with continuous improvement in mind to make a high quality glove now and for the future generations.