Low Carbon Production

SDG 7 (Affordable and Clean Energy)

Sri Trang Group appointed an Energy Conservation Committee to manage energy consumption, develop energy efficiency improvement measures, and promote renewable energy consumption. So far, we have changed our machinery parts with energy-saving equipment, and we have implemented solar rooftop and lighting systems to produce electricity for the use in our factories. Furthermore, we use rubber tree woodchip as biomass – a renewable energy source – for heat production in boilers rather than depending on fossil fuels to reduce our carbon footprint.

SDG 13 (Climate Action)

Climate change is a serious global issue posing adverse climate-related risks and impacts on economies,business operations, and lives. Because climate change impacts are intensifying, several climate ambitions and efforts to limit the global temperature rise to well below 1.5°C have been initiated by various countries to prevent irreversible impacts. Sri Trang Gloves is aware of climate change impacts which may disrupt our business operations. Because of this, as a sustainable medical rubber gloves producer, we have implemented GHG emissions reductions initiatives, such as solar roof, energy efficiency improvement, and biomass usage, to reduce carbon footprints in all aspects of our business activities to pursue our long-term target of becoming a low-carbon company. Besides obtaining our latex raw material from rubber trees, we use rubber tress to combat climate change and create sustainability in our value chain in three ways.

100% Biomass Renewable Energy Production Facility

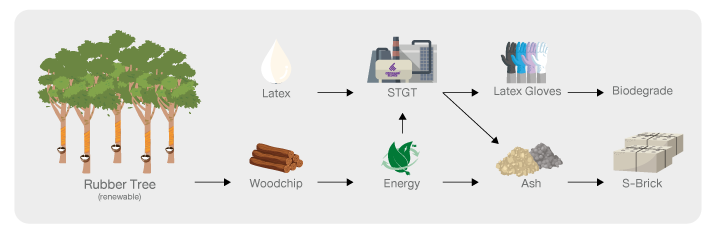

Due to Sri Trang Gloves’ “Clean World” brand promise, we focus on sustainable business operations throughout the value chain to produce low-carbon products, combat climate change, and support the global and national net-zero emissions target. We have mainly used woodchip obtained from rubber trees once they stop producing latex as biomass for thermal energy production for the use in our rubber glove production processes.

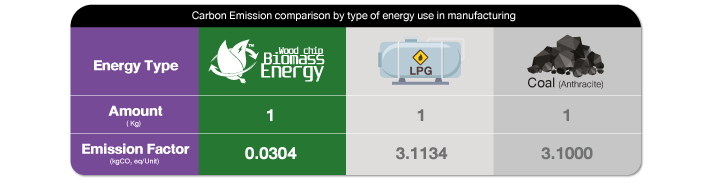

The use of biomass, which is a renewable energy source, helps reduce GHG emissions significantly due to its lower emission factors compared with fossil fuels. In addition, because rubber trees capture CO2 in the atmosphere throughout their life cycle for the growth, their biomass combustion for energy can also be recognized as a carbon-neutral energy source. Therefore, the use of biomass for energy production results in notably low GHG emissions intensity (GHG emissions per rubber gloves produced) for our rubber glove production facilities.

Because the highest proportion of our energy consumption is thermal energy produced from biomass, this makes Sri Trang Gloves a leading low-carbon manufacturing company in the market.

- SET-AGRO & SET-RESOURC include Thai listed companies in Group 1 and Group 2 which are categorized in SET-Agro & Food Industry Sector and SET-Resource Industry Sector respectively.

- SET-Industry Group 1 includes Thai listed companies in that industry sector which have market cap more than THB 100,000 million.

- SET-Industry Group 2 includes Thai listed companies in that industry sector which have market cap more than THB 30,000 million, but not greater than THB 100,000 million.

- Only STGT is categorized in the SET-CONSUMP Industry Sector Group 2.

- STGT is categorized in the SGX-Healthcare Service Industry Sector.

- All GHG emissions, except for STGT, are presented in the average values.

- GHG emissions presented in the figure cover scope 1 & scope 2 GHG emissions

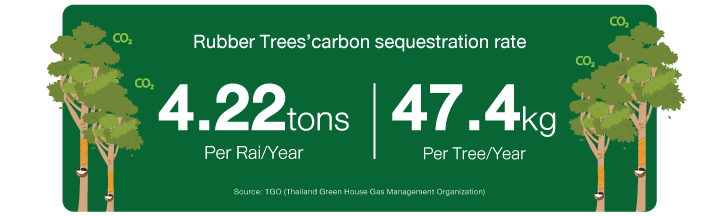

Rubber Tree Plantation as a Potential Carbon Sequestration Source

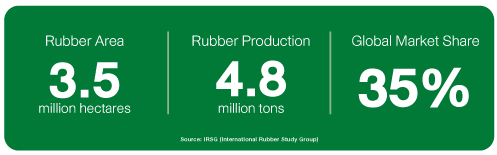

Thailand is the world’s largest natural rubber producer in the global market. In 2021, Thailand’s rubber plantations comprised 3.5 million hectares (22 million rai or 8.6 million acres) producing up to 4.8 million tons of rubber raw materials, which was 35% market share of global rubber supply.

Besides latex, rubber trees have high potential for carbon sequestration through photosynthesis and stored CO2 as biomass. This potential makes rubber tree plantations valuable carbon stock assets to reduce CO2 and generate carbon credits in pursuit of the climate ambitions.

At the end of their years-long life cycle of producing natural rubber, natural rubber trees are cut down and destined for use as biomass energy. The plantations are expertly managed and new crops are planted to ensure the natural resources of the land are maintained. Re-planting new rubber trees also allows soil and environments in the plantation areas to recover while capture and store CO2 emissions from the atmosphere. This reflects environmental sustainability of rubber tree plantation cycle. The use of felled rubber trees and their woodchip as biomass for renewable energy is a perfect solution to reduce excessive end-of-life rubber trees and to increase renewable energy consumption in our production enhancing the value of rubber tree utilization.

Circular Economy for Rubber Trees

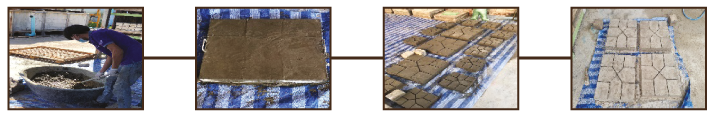

In addition to biomass energy, we seek for opportunities to take advantages of waste utilization to reduce waste disposal. Employing a Circular Economy concept, we focus on adding value for wastes and their by-products. For example, our S-Brick Project uses ashes from the biomass combustion in our boiler to produce paving bricks. The paving bricks are used for landscape improvement around our factories and provided to local communities and rubber farmers for their own uses.

Sri Trang Gloves is consistently developing waste management initiatives to reduce waste disposal, prevent environmental impacts, and create added value throughout our value chain.